bend tables for sheet metal materials To create your own bend table, copy and edit this bend table with any text editor. . We are a factory offering OEM Precision CNC Machining Rapid Prototyping Service. Specialized in CNC Turning Milling of Brass Lamp Parts. High quality, customizable, and reliable!

0 · stainless steel bend chart

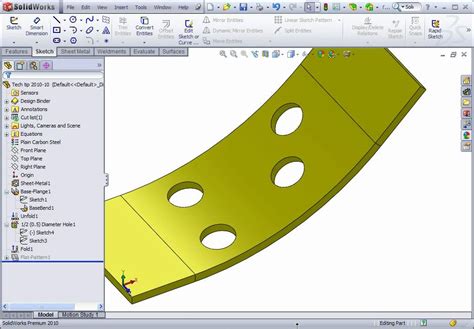

1 · solidworks sheet metal round bend

2 · solidworks k factor bend table

3 · sheet metal gauge chart excel

4 · sheet metal bending radius chart

5 · sheet metal bend solidworks

6 · sheet metal bend chart

7 · sheet metal bend allowance table

Wholesale aluminum CNC milling parts or custom aluminum milling parts, welcome to contact us. Milling is a metal cutting process that is completed by moving the rotating tool and workpiece into the spindle. Milling can be on the workpiece plane processing, groove processing, tapping, drilling, reaming, boring, chamfering, and gear processing.

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. . s = material thickness; r = bend .To create your own bend table, copy and edit this bend table with any text editor. .

Sheet metal gauge/bend tables store properties for a designated material. A .

To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of .A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. If a specific bend angle or bend radius is not in the .

In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data. By setting up a sheet metal gauge table for your project, it can dramatically speed up your workflow by making the selection of the bend radius and the right wall thickness of the .

stainless steel bend chart

Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material.

In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples.You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. . s = material thickness; r = bend radius; k-factor = k-factor (you can use an equation or a value)

To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of measure in the Unit row of the bend table.

A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. If a specific bend angle or bend radius is not in the table, the flat pattern analyzer interpolates between adjacent cells to determine a value.

solidworks sheet metal round bend

In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data.

By setting up a sheet metal gauge table for your project, it can dramatically speed up your workflow by making the selection of the bend radius and the right wall thickness of the material readily available.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material.

In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples.Sheet metal bend tables allow you to specify a sheet metal part’s bend allowance or bend deduction values. The bend table also includes bend radius, bend angle, and part thickness values. Bend tables are accessible in text files and Microsoft Excel spreadsheets.

Accurate bend deductions are key to delivering high-quality sheet metal parts. To streamline your design process and ensure your parts are manufactured without delays, we’ve created easy-to-use bend deduction tables specifically for our shop’s equipment and processes.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. You can also use individual gauge tables and bend tables. See Sheet Metal Gauge Table and Bend Table Overview.

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. . s = material thickness; r = bend radius; k-factor = k-factor (you can use an equation or a value)To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of measure in the Unit row of the bend table.A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. If a specific bend angle or bend radius is not in the table, the flat pattern analyzer interpolates between adjacent cells to determine a value. In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data.

solidworks k factor bend table

By setting up a sheet metal gauge table for your project, it can dramatically speed up your workflow by making the selection of the bend radius and the right wall thickness of the material readily available.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material.

In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples.Sheet metal bend tables allow you to specify a sheet metal part’s bend allowance or bend deduction values. The bend table also includes bend radius, bend angle, and part thickness values. Bend tables are accessible in text files and Microsoft Excel spreadsheets. Accurate bend deductions are key to delivering high-quality sheet metal parts. To streamline your design process and ensure your parts are manufactured without delays, we’ve created easy-to-use bend deduction tables specifically for our shop’s equipment and processes.

wmw metal fabrics ltd

wood cnc machine reviews

Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Tolerance down to 0.001 inches. Choose from 100+ materials, 60+ surface finishes. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified. Experience lead times as short as 1 day. Start a New CNC Project!

bend tables for sheet metal materials|sheet metal bend allowance table